A-Team Program

Imagine what you could build with A-Team of skilled roboticists. What would you want to learn? What would you help others learn?

Imagine what you could build with A-Team of skilled roboticists. What would you want to learn? What would you help others learn?

Stop wasting your time on starting from the beginning. Jump in with both feet. We can help you learn as you go, and think you should get building!

Our Teams work with expensive and highly advanced robotics technologies you would never have access to on your own.

● — — – topics – — — ●

The team projects are usually 3 month sessions. Pick the project that

encompasses the skills and session timing that works for you.

We modify this widely used industry standard project management approach for a flat leadership structure. Everyone gets experience running teams and setting the pace, guided by our advisors and mentors. These are the leadership and soft skills that every employer wants, yet you can only get by being on a team.

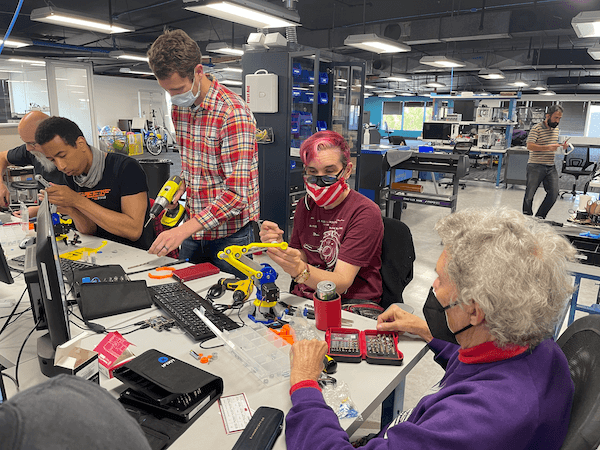

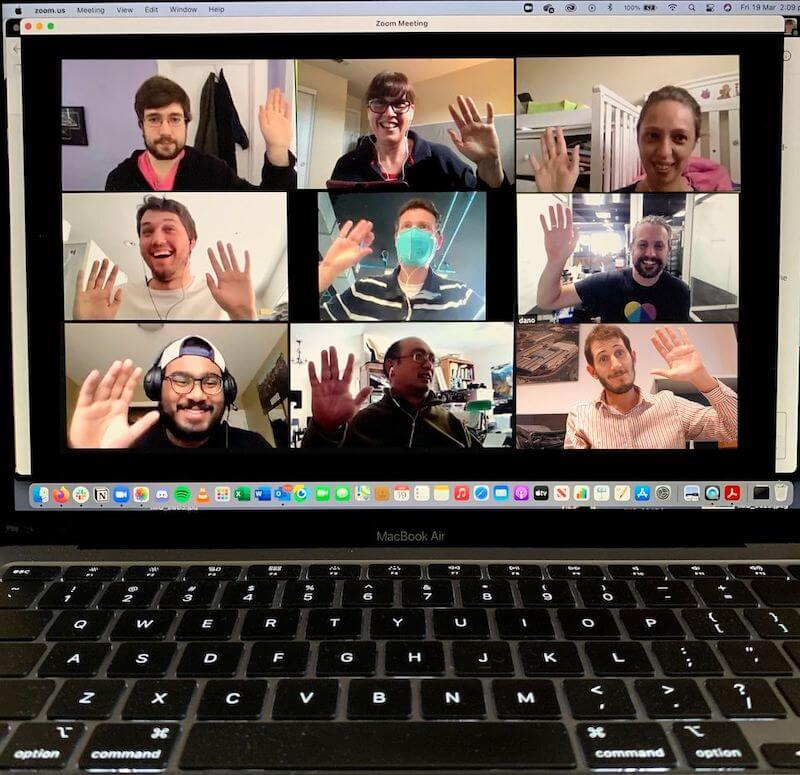

Study Hall is when the team comes together to get work done. Remote members push code, CAD, and designs. In-Person teams assemble, test, and validate. Sometimes the opposite and everything in-between. Work outside this sessions is also expected and necessary. Mentors and guest-experts will be there to get you through the hurdles and accelerate your progress.

Documentation is a requirement of any team projects, plus we want you to show off your work! Tutorials are due each week give you a chance to demonstrate your newly acquired skills, make a record of your progress, and earn badging through our system. Badges are a demonstrable way to show you have verifiable mechatronics experience and skill. Tutorials, badges, and projects will be showcased on your public profile. Show what you know, what you’ve built, and what your potential is!

hybrid hands-on<

Getting hands-on robotics experience has never been easier

The only pre-requisite for our team program is some experience in one skill area in the project. As your skills grow you’ll be able to apply to bigger more audacious projects.

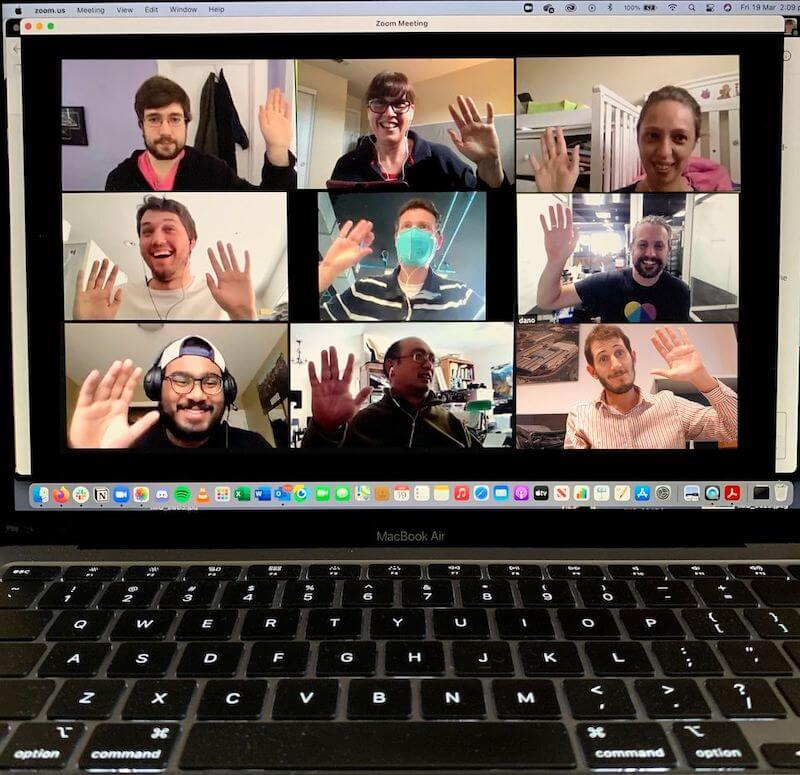

Students can participate virtually or in person, or both. We recommend 20 hours per week commitment for this program to be effective, however you will get out of it what you put into it. Three group sessions a week are required, but can be attended asynchronously if necessary.

We are expanding the areas we offer micro-credentialing in. When you complete a team program you'll recieve a verifiable NFT that you can display on your resume, social media, or anywhere else to prove you have successfully completed a mechlabs program.

Boston Dynamics Spot Robot

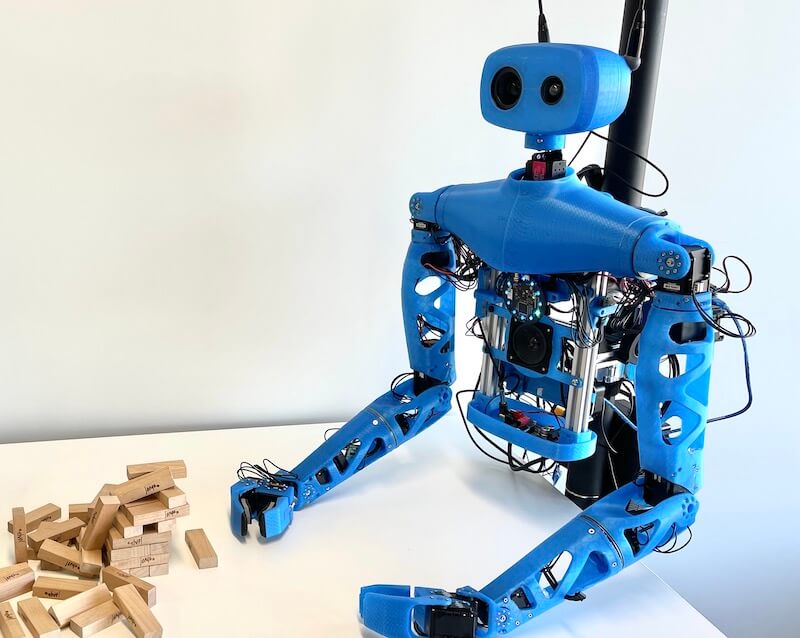

Reachy

Build a custom robot to navigate a series of challenges

Nights and Weekends - everyone builds their own!

● — — – Student Profile – — — ●

Nahuel, who is from Argentina, has been joining us remotely. Despite power outages, difficult internet access, working full time, and English not being his native language; he overcame all that to thrive within our program!

Nahuel has excelled in the program learning a variety of skills. The opportunity to learn hands-on in a project-based robotics program is what drew him to apply.

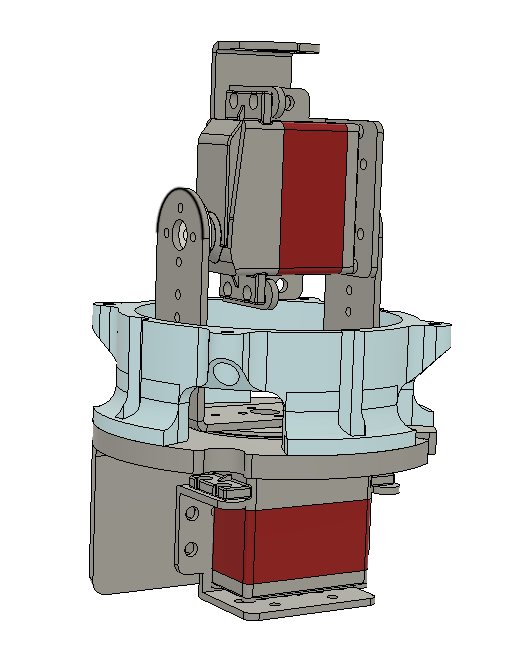

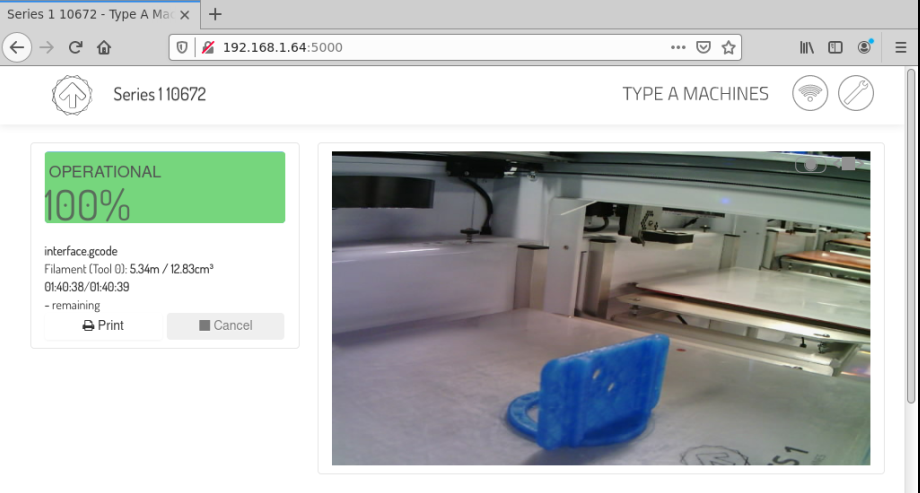

We were designing a pan tilt servo mechanism for the neck of our bot. Nahuel has been leading the charge and learning 3D Parametric CAD modeling from scratch. With just a short primer session with one of our mentors, Nahuel was learning 3D design. Each morning the latest version of his design was sitting on our 3D printer (printed 100% remotely), ready for assembly, and Nahuel awaiting notes on changes needed for the next iteration.

Within less than two weeks Nahuel was designing more complex assemblies and his designs were immediately being built into functional mechanisms. It takes most people months to build a proficiency in 3D CAD modeling.

Mentors were there to give him the next step, tips to avoid pitfalls, and precisely what he needed. He moved from design to iteration immediately. So much is learned when printing, assembling and testing a design. From tolerances to structural failures, it is faster to learn by doing.

The team needing his designs to be assembled to move forward, created positive accountability and motivation. Access to advanced prototyping equipment, tools, and a community of experts at Circuit Launch, even remotely.

Mentors were there to give him the next step, tips to avoid pitfalls, and precisely what he needed. He moved from design to iteration immediately. So much is learned when printing, assembling and testing a design. From tolerances to structural failures, it is faster to learn by doing.

The team needing his designs to be assembled to move forward, created positive accountability and motivation. Access to advanced prototyping equipment, tools, and a community of experts at Circuit Launch, even remotely.

His contribution is now part of our open source project and provides functionality that is in reach of thousands of robotics enthusiasts interested in our projects.